Fascination About Digital Printing

Digital Printing - The Facts

Table of ContentsDigital Printing Can Be Fun For EveryoneExcitement About Digital PrintingDigital Printing Fundamentals ExplainedTop Guidelines Of Digital Printing10 Easy Facts About Digital Printing ExplainedFacts About Digital Printing UncoveredDigital Printing Can Be Fun For AnyoneThe Basic Principles Of Digital Printing

Modification additionally permits businesses to stick out in a congested market by producing distinct advertising and marketing products that distinguish them from their competitors. One of the main advantages of electronic printing is the capacity to print variable information. Each published piece can be unique, enabling companies to create personalized marketing products that talk directly to their target market.Digital printing additionally permits for personalization in the design of advertising materials (Digital Printing). With electronic printing, companies can develop layouts that are special and customized to their certain needs.

Not known Facts About Digital Printing

This benefits organizations that wish to examine different marketing methods or release new product or services. By publishing smaller sized amounts of marketing products, services can decrease waste and prevent the need for excess inventory. Digital printing is also versatile. It can print on different products, consisting of paper, cardstock, plastic, and steel.

By using various materials and styles, companies can develop unique advertising and marketing materials that stick out from their competitors and stand out from their target market. Digital printing additionally uses consistency. With traditional printing approaches, there is usually variation between prints as a result of distinctions in ink coverage, pressure, and other aspects.

This uniformity can assist construct client depend on and trustworthiness, showing that the business is devoted to providing premium products. Consistency is specifically essential for companies that wish to construct client trust fund and trustworthiness. By making sure that every print is constant, businesses can reveal that they are committed to giving high-grade products and paying interest to the details.

Some Of Digital Printing

Additionally, digital printing generates much less waste due to the fact that it can print as needed and in smaller amounts, reducing the need for excess stock and products. Digital printing additionally uses less energy compared to conventional printing techniques. Digital printers do not need as much power to run, as they do not require to heat up as much or use as much power to run.

The Best Guide To Digital Printing

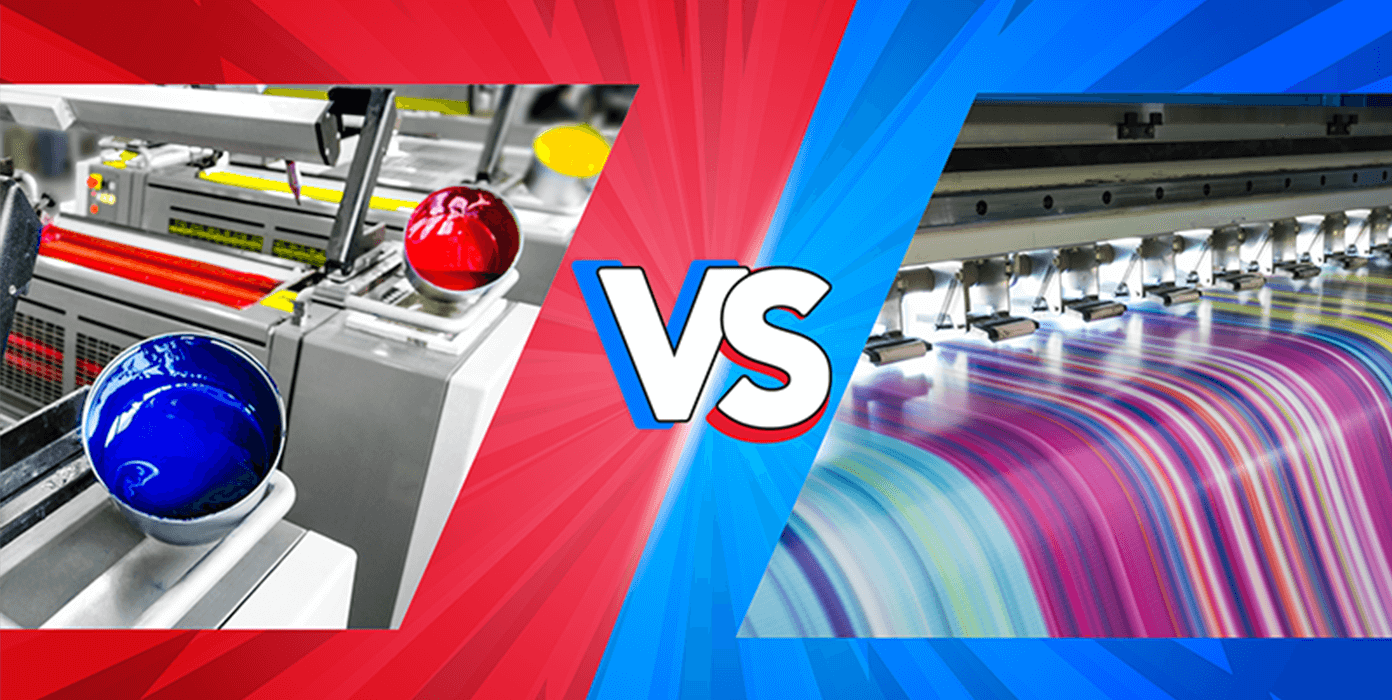

Offset printing needs a plate for each shade published. Standard offset printing is a print approach that uses aluminum plates to move ink onto a rubber sheet (frequently described as a "blanket"). The picture is after that rolled onto the printing surface area. This printing method is thought about "countered" because the ink is not transferred to the paper directly.

Getting My Digital Printing To Work

The equipment's set up prices are high originally, extra units end up being fairly less costly as the amount boosts. Offset printing enables a large range of print products to be utilized during production. It enables the printer to utilize different paper kinds, custom finishes, and various inks. The high-grade photos created through countered printing make it the favored method, especially amongst visuals developers, when seeking the best shade reproduction, detail, and professional-looking prints.

For digital inkjet printing, ink is transferred directly onto the surface. Instead than depending on light weight aluminum plates and rubber blankets to move an image, digital printing utilizes liquid ink throughout manufacturing.

What Does Digital Printing Mean?

Much better color integrity describes both the precision of the colors and their balance in the layout. Because offset printing can mix personalized shade inks for each and every job, it will naturally get the shades spot-on. Works equally well on almost any sort of material. Reliable, premium photo high quality. Count on offset printing this post for clean, distinct types and pictures without streaks or areas.

It costs a great deal to start a balanced out job. You need to spend money into producing the plates, which takes time. Once you have actually invested it, all of the products are all set to go, and you'll spend much less on huge balanced out jobs than an electronic print, which is about the same per item no issue how home large the job gets.

Digital printing is less expensive for low-volume work. The price per system goes down for digital printing, so at some factor, they crisscross. Transforming information within a single print work.

An Unbiased View of Digital Printing

While digital printing or inkjet printing is the preferred choice in the existing times, there are compelling factors to transform from countered to electronic printing systems. When printing offset or digitally, crucial choices and procedures are included in color matching.

Whichever the situation, the color will require to be matched. Color matching of digital printer ink is no more testing with dyes and pigments. Industrial inkjet printing uses adaptability for printing on lots of different substrates. Digital printing is ideal for customers that do not require longer runs and warehousing materials.

One benefit of electronic printing is choosing from a vast array of digital substrates. With balanced out printing, substratums compose, generally, 30% of the expense of the work. With electronic printing, the price of the substrate in the general task is tiny. This enables more options than in the past, which's excellent for marketing professionals and businesses.

The Greatest Guide To Digital Printing

drop-on-demand is the second printing innovation to think about. Continual inkjet systems require considerable maintenance, more driver training, and higher downtime. However, equipment prices in inkjet printing are far lower than offset printing as there are no plate-making, plates, and press expenditures. Beyond the resources cost, the prepress tools and printing machine require very skilled drivers in offset printing, which adds labor expenses.